REPBULIC OF YEMEN

Yemeni Est. For Cement Manufacturing and Marketing

Report

on Micfil Ultra-Fine filtration Module

For Engine Lubricant and Fuel

|

Excavator Spec |

|

|

Manufacturer |

TEREX |

|

Model |

RH40 |

|

Production Year |

2006 |

|

Engine

Type |

CUMMINS |

|

Engine No. |

|

|

Engine

Model |

OSK19C |

|

Engine Production Year |

2006 |

|

Engine

Capacity kW |

485/650 |

|

Oil Tank Capacity |

70L |

|

Pistons |

6 |

Trial

The Excavator was selected for the purpose of proofing the claimed efficiency

of Micfil Ultra-Fine Filtration Modules, by conducting the following

comparisons:

1)

Reduce metal soot

contaminants in the lubricant.

2) Extending intervals to engine's lubricant oil change.

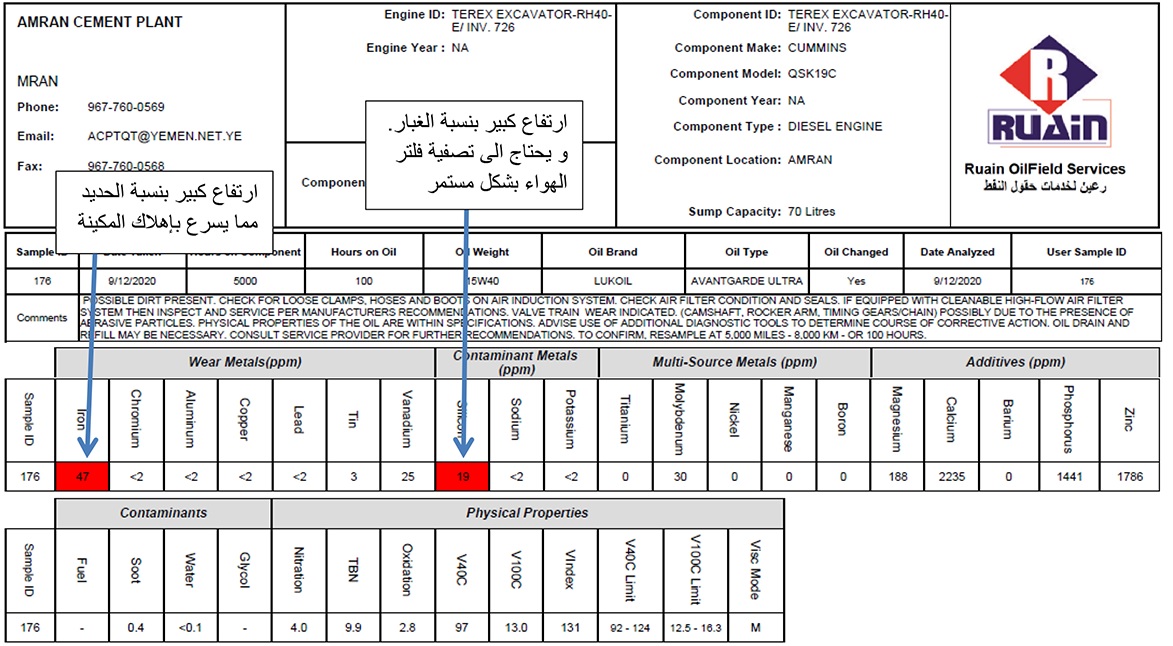

Engine Oil analysis report from before installing Micfil Module:

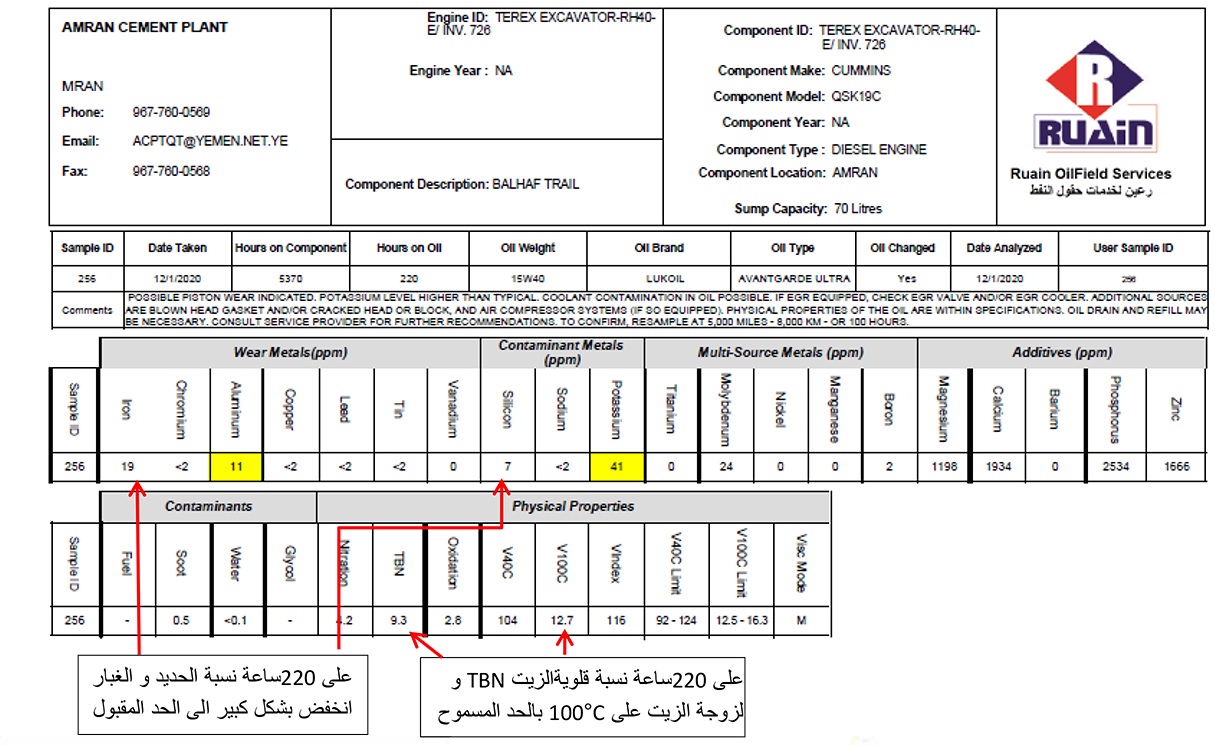

Engine Oil analysis report from After installing Micfil Module:

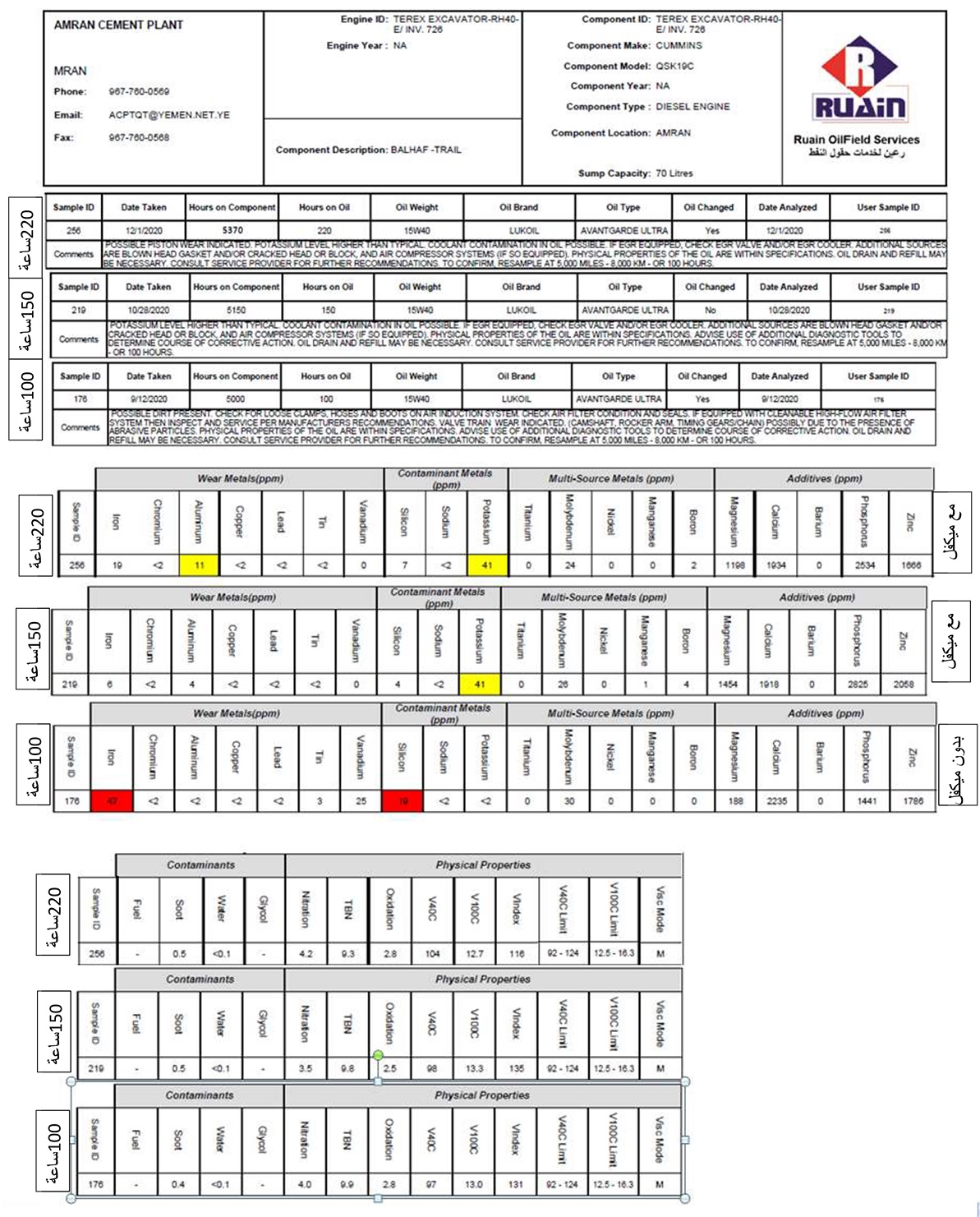

All three analysis reports side-by-side for comparison:

Analysis report summary before Micfil

Module installation:

1)

High Iron soot contamination levels *Risky of: 47ppm @ 100hrs operating

duration.

2)

High external contaminants (Silicon "dust") *Risky of: 19ppm

@ 100hrs operating duration.

Analysis report summary after Micfil Module installation:

1)

Reduction in Iron soot contamination levels *Safe of only: 19ppm @ 220hrs

operating duration.

2)

Reduction of external contaminants (Silicon "dust") *Safe of

only: 7ppm @ 220hrs operating duration.

Below table highlights the difference in

the analysis reports BEFORE and AFTER installation of Micfil Ultra-Fine filtration

module:

|

|

Iron Soot ppm |

External Contaminants soot ppm |

Operating Duration |

|

Before Micfil Installation |

47 |

19 |

100 hrs |

|

After Micfil Installaion |

19 |

7 |

220 hrs |

|

Balance |

28 |

12 |

120 hrs |

Most crucial factors to be taken for

measuring engine oil's quality and usage validity are:

![]() Total Base Number (TBN) which determines the oil's enjoinment wither alkaline

or acidic.

Total Base Number (TBN) which determines the oil's enjoinment wither alkaline

or acidic.

![]() Viscosity rates @ water boiling degree of 100C˚ Celsius.

Viscosity rates @ water boiling degree of 100C˚ Celsius.

|

|

Total Base Number (TBN) |

Viscosity Rate @100 Degree Celsius |

Operating Duration |

|

Before Micfil Installation |

9.9 |

13 |

100 hrs |

|

After Micfil Installaion |

9.3 |

12.7 |

220 hrs |

|

Balance |

0.6 |

0.3 |

120 hrs |

Summary: Notably that Micfil Ultra-Fine Filtration Module successfully

filters Metal contaminants soot (hereby: Iron soot and Silicon

"dust" contamination) with improving TBN and Viscosity rates by

maintaining safe levels at 220hrs operating duration. Clearly, oil's validity was safely extended up to

250hrs. Oil analysis must be repeated at 250hrs of operating duration. |

As per analysis reports, where it showed slight increases in deposits of metals: iron and aluminum, which is decisive evidence of an increase in the rate of wear on the metal surfaces of cylinders and crankshafts as a result of the friction of metal parts, Balhaf Solutions strongly recommends conducting chemical overhauling by using XADO revitalization products, then repeat the analysis to realize the difference.

355 Comment(s)

gdfh

sdfrveif dwcs

We offer a 6$ sale on a large collection of handmade beaded bracelets. All bracelets are made with love and available in multiple colors.

A blog post has made blogging their business. Business is a very risky job to do. You have to take many risks rather they are from nursing research paper rational or irrational you have to take some steps in life to achieve something.

I have been looking for this information for a long time, I was very surprised when I found it here.

I’ve bookmarked this site so hopefully I will discover much more on this topic in the foreseeable future.

Forget the stress of submitting a substandard essay when our experts are ready to tackle your assignment with professionalism. Therefore, buy term paper from us and free up your time to concentrate on essential commitments. Catch up with your family and friends, pursue your passion outside class and relax while we handle all your assignments.

The OpenCart theme is so popular especially for the new ones who are trying to grasp on using the platform.

Mazmo UAE provides premium quality drainage tanker services at the best prices! We provide the most popular and simple way of managing wastewater for properties that can’t connect to the public sewer system. Mazmo UAE has all the expertise you need for that, along with local coverage and a full range of septic tank and cesspit services!

If you do decide that is your custom writers help service for you, you'll find a couple ways to contact the company if you want to. Referring to this contact page, you will come across that number along with an email form you can fill out.

So, if you are short on time, don’t hesitate to get instant essay help at. Here’s how it works. All of them hold advanced degrees and have been involved in academic writing for at least two years.

This one is another summative point for all the professions that we have. Thank you for sharing.

Good post. I think I may be a little to late to vote though.

I also let my colleagues know about this.

So, if you are short on time, don’t hesitate to get instant essay help at. Here’s how it works. All of them hold advanced degrees and have been involved in academic writing for at least two years. <a href="https://www.google.com">test</a>

Thank you for the update, very nice site..

Having tried all the other additives from the more established brands, I kept my expectations modest to avoid frustrating myself after making a high priced additive purchase. I followed instructions but never felt any difference after the idle run which some said it will be felt immediately. I drove the car for 30miles and then gradually noticed the improvement. Engine noise remains same however I can tell the roar is more refined and power transfer is way more seamless. Vibration was also considerably lessened and the overall ride experience has improved. I can tell that the engine is way more responsive.

Intimately, the article is in reality the best on this precious topic. I agree with your conclusions and also can thirstily look forward to your coming updates. Just saying thanks definitely will not simply just be sufficient, for the phenomenal lucidity in your writing. I can at once grab your rss feed to stay informed of any updates. Fabulous work and much success in your business dealings!

I simply had to thank you very much once again. I’m not certain what I could possibly have followed in the absence of the type of ideas contributed by you concerning my theme. It actually was a frightful difficulty for me, nevertheless finding out the very professional manner you resolved the issue forced me to jump over joy. Now i’m thankful for your work and even hope that you are aware of a great job you’re doing training people today thru your blog post. I know that you have never got to know any of us.

I adore your website.. excellent colours & theme. Did an individual design this site oneself or maybe have you actually rely on someone else to do it for you personally? Plz answer while I!|m planning to design and style my very own blog site as well as want to learn where by u became this specific through. thanks

How much of an helpful document, hold publishing special someone

Some truly interesting points you have written. Assisted me a lot, just what I was looking for .

You made some decent points there. I looked on the net for that problem and discovered most people will go coupled with using your web site.

The post is definitely nicely written but it contains many useful facts. I am just ready to find your distinguished way of writing the post. So now you make it easy for me to learn and implement. Nice one for sharing around.

i wish to have some diamond necklace but they are quite expensive::

Christina Sauls

When I originally commented I clicked the -Notify me when new surveys are added- checkbox and already whenever a comment is added I receive four emails with similar comment. Perhaps there is by any means you can eliminate me from that service? Thanks!

pay per click programs are really great, i could earn some decent cash from it..

Usually I do not read post on blogs, but I wish to say that this write-up very pressured me to take a look at and do it! Your writing style has been amazed me. Thanks, very nice post.

Hi. your blog is full of comments and it is very active,

Hi. your blog is full of comments and it is very active,

Hi. your blog is full of comments and it is very active,

howdy, I am having bad luck attempting to rank up for the words “victorias secret coupon codes”… PLEASE approve my comment!!

Nice information, appreciate it in the author. It really is incomprehensible in my opinion now, but in general, the usefulness and significance makes my head spin. Many thanks and all the best!

Aw, it was an incredibly good post. In idea I would like to put in writing similar to this additionally – spending time and actual effort to have a really good article… but what things can I say… I procrastinate alot and also by no means manage to go completed.

Amazing plenty of good information.

Good stuff. Cheers!

You actually expressed it superbly.

You actually expressed it superbly.

Tips very well considered!

Good stuff. Cheers!

Amazing plenty of good information.

Amazing plenty of good information.

You definitely made the point.

Tips very well considered!

You definitely made the point.

You’re a master of the written word!

Very good

You definitely made the point.

You have made the point!

Amazing plenty of good information.

You actually expressed it superbly.

Amazing plenty of good information.

You actually expressed it superbly.

You definitely made the point.

You actually expressed it superbly.

Nicely put, Cheers.

Superb postings. With thanks.

Amazing plenty of good information.

Fantastic data, Thanks a lot!

Fantastic data, Thanks a lot!

Nicely put, Cheers.

You definitely made the point.

Fantastic data, Thanks a lot!

Fantastic data, Thanks a lot!

You have made the point!

Amazing plenty of good information.

You said it perfectly.

You definitely made the point.

Amazing plenty of good information.

You have made the point!

You have made the point!

Fantastic data, Thanks a lot!

Fantastic data, Thanks a lot!

You definitely made the point.

Superb postings. With thanks.

You’re a master of the written word!

Very good

You said it perfectly.

Superb postings. With thanks.

Superb postings. With thanks.

Nicely put, Cheers.

Fantastic data, Thanks a lot!

You definitely made the point.

Superb postings. With thanks.

Fantastic data, Thanks a lot!

Superb postings. With thanks.

Nicely put, Cheers.

You definitely made the point.

Superb postings. With thanks.

You have made the point!

Good stuff. Cheers!

You’re a master of the written word!

Very good

You said it perfectly.

Fantastic data, Thanks a lot!

You definitely made the point.

You’re a master of the written word!

Superb postings. With thanks.

Amazing plenty of good information.

Tips very well considered!

You said it perfectly.

You definitely made the point.

You actually expressed it superbly.

Fantastic data, Thanks a lot!

Fantastic data, Thanks a lot!

Good stuff. Cheers!

Tips very well considered!

Tips very well considered!

Tips very well considered!

You definitely made the point.

You actually expressed it superbly.

Amazing plenty of good information.

You have made the point!

You have made the point!

You have made the point!

Amazing plenty of good information.

You said it perfectly.

Tips very well considered!

Good stuff. Cheers!

Superb postings. With thanks.

Fantastic data, Thanks a lot!

You actually expressed it superbly.

Good stuff. Cheers!

You said it perfectly.

You definitely made the point.

Amazing plenty of good information.

There are lots of interesting points outlined in this article but I don’t know if I go along with every one of them. There is certainly some validity but I am going to hold my opinions until I look into it more. Fine article, thanks and we want more! Added to FeedBurner too

Thank you for an additional great post. Exactly where else could anybody get that kind of facts in this kind of a ideal way of writing? I have a presentation next week, and I’m around the appear for this kind of data.

I conceive you have noted some very interesting details , regards for the post.

I conceive you have noted some very interesting details , regards for the post.

Dreamin. I love blogging. You all express your feelings the right way, because they are your feeling, focus on your blog it is great.

Nice information, valuable and excellent design, as share good stuff with good ideas and concepts, lots of great information and inspiration, both of which I need, thanks to offer such a helpful information here.

Oh my goodness! an amazing article dude. Thank you However I am experiencing issue with ur rss . Don’t know why Unable to subscribe to it. Is there anyone getting identical rss problem? Anyone who knows kindly respond. Thnkx

Thank you, 오피가이드, for the intimate and exquisite experiences you provide through your sensual massages.

Great post man, keep the nice work, just shared this with my friendz

I found the perfect service providers through 오피사이트's curated listings. Satisfaction guaranteed.

Elevate your self-care regimen with 전주오피 (Jeonju Op-site), delivering a range of soothing sensual massage, therapy, and men's spa opportunities.

[url=https://www.springbord.com/]springbord systems[/url]

Win big and safely with this top 토토사이트 operator.

출장마사지's mobile massage is a delightful treat. The therapists are skilled and professional.

If you want to find a legal 토토사이트 in Korea, find it in Toto Safe Guide.

Impeccable service from 에볼루션카지노추천; they ensure a smooth and enjoyable casino journey.

Trust 토스카지노 꽁머니 (Tos Casino Free Credits) for verified Toto sites, ensuring secure and rewarding gaming options in Korea.

Discover authentic Toto entertainment with 꽁머니 (Free Credits), offering secure and enjoyable gaming experiences in Korea.

오피소개 is genuine, providing accurate profiles of sensual massage therapists. Trusted information for a satisfying experience.

Most beneficial gentleman speeches and toasts are made to enliven supply accolade up to the wedding couple. Newbie audio system the attention of loud crowds should always think about typically the great norm off presentation, which is their private. best man speaches

Elevate your massage encounters with 광명오피's expertise. Discover relaxation and rejuvenation like never before.

Discover the true essence of sensual massage with 유흥사이트's authentic profiles and professional therapists.

Reflecting on my 다낭 황제여행, Danang's grandeur and charm made it a journey fit for royalty and adventure seekers alike.

Elevate your gaming adventure with 에볼루션카지노사이트. Big wins and excitement await.

Impressive selection of free sports on 해외축구중계. Love it!

aa den stora boken… [...]p Have you noticed any performance problems with the wordpress platform? I ha oj[...]…

you might have a fantastic weblog here! would you wish to make some invite posts on my weblog?

오피사이트 (op-site) introduces men-only spas that promise a retreat from everyday stresses.

As far as me being a member here, I wasn’t aware that I was a member for any days, actually. When the article was published I received a notification, so that I could participate in the discussion of the post, That would explain me stumbuling upon this post. But we’re certainly all members in the world of ideas.

Thank you of this blog. That’s all I’m able to say. You definitely have made this web site into an item thats attention opening in addition to important. You definitely know a great deal of about the niche, youve covered a multitude of bases. Great stuff from this the main internet. All over again, thank you for the blog.

Hello, i think that i saw you visited my site thus i came to “return the favor”.I am trying to find things to enhance my web site!I suppose its ok to use some of your ideas!!

very nice post, i actually love this web site, carry on it

This is my first time i visit here. I found so many entertaining stuff in your blog, especially its discussion. From the tons of comments on your posts, I guess I am not the only one having all the enjoyment here! Keep up the excellent work.

Amazing plenty of good information.

Fantastic data, Thanks a lot!

You have made the point!

You definitely made the point.

Nicely put, Cheers.

You definitely made the point.

Nicely put, Cheers.

Tips very well considered!

Fantastic data, Thanks a lot!

Fantastic data, Thanks a lot!

Superb postings. With thanks.

You’re a master of the written word!

Elevate your wellness journey with Korea's premier mobile massage offerings. Recharge and rejuvenate through convenient 출장 therapies.

You definitely made the point.

You definitely made the point.

You have made the point!

Prioritize indulgence with 오피, your gateway to top-notch massage establishments.

Unlock blissful massages with 오피아트's expertise in brokering excellence.

You definitely made the point.

Good stuff. Cheers!

You’re a master of the written word!

You’re a master of the written word!

Superb postings. With thanks.

Tips very well considered!

Amazing plenty of good information.

Fantastic data, Thanks a lot!

You’re a master of the written word!

Very good

You have made the point!

Elevate your relaxation game with 오피가이드's commitment to quality massage companies.

Discover top-tier massage therapists and services, courtesy of 오피가이드.

Nicely put, Cheers.

You’re a master of the written word!

Good stuff. Cheers!

I'm always impressed by their consistency in excellence.

Every song is a new adventure at 인천셔츠룸 Karaoke.

Keep your streaming activities private and secure with 누누티비.

Bet with confidence on 메이저놀이터's trusted platform.

Watch live soccer broadcasts comfortably via 축구중계 without leaving your residence.

Unveil the magic of 텐텐벳. With its exceptional odds and diverse Toto options, it's where winning dreams come true.

You’re a master of the written word!

Nicely put, Cheers.

Very good

Amazing plenty of good information.

Fantastic data, Thanks a lot!

Superb postings. With thanks.

You definitely made the point.

You’re a master of the written word!

Fantastic data, Thanks a lot!

You said it perfectly.

You actually expressed it superbly.

Nicely put, Cheers.

You’re a master of the written word!

You’re a master of the written word!

Tips very well considered!

Very good

Ready to destress? The 휴게텔 offers exceptional massage services.

You actually expressed it superbly.

You have made the point!

You definitely made the point.

오피사이트's regional categorization is a fantastic feature for users.

Interesting points raised, thank you for sharing. I would like to see more posts like this.

Great article. Thank you for sharing your insight on this topic.

Discover serenity and wellness with 출장안마, your top choice.

For a secure gaming experience, opt for 안전놀이터 that validate Toto Match.

문제로 두 번이나 초대형 계약을 놓쳤다. 2022년 시즌이 끝난 뒤 옵트아웃을 선언하고 FA 시장에 나온 코레아는 https://bmopart.com/ 오피사이트

같은해 12월

원자재 폭락 속 철광석값 상승 鐵 쓸어담는 中철강업계 탓 https://cpurams.com/

트럼프 첫 경선서 압도적 1위 질주 바이든 미국에 위협 맹비난 https://cpurams.com/

미얀마 아프가니스탄 제치고 세계 최대 아편 생산국 https://cpurams.com/

日 기시다파 하야시 관방장관 등 非아베파로 각료 4명 교체 https://cpurams.com/

루시드 리비안 폭등 금리인하 기대감에 美 전기차 랠리 https://cpurams.com/

北 軍위성 이어 공중조기경보통제기까지 갖나? 대형화물기로 제작중 https://cpurams.com/

김정일 사망 12주기 탄도미사일 쏜 北 미국 핵잠수함 부산 입항 https://cpurams.com/

일본제철 산업화 상징 US스틸 품었다 철강 세계 3위 우뚝 https://cpurams.com/

Olyan honlapon hirdethető meg az eladó vállalkozás, amely kifejezetten adequit eladó cégek hirdetéseire szolgáló platform, ahol így részletesen kereshet eladó cégek hirdetései között.

Great article. Thank you for sharing your insight on this topic.

철강 역사 122년 美 US스틸 일본에 팔렸다 https://cpurams.com/

비트코인 다시 5600만원 찍었다 연말 랠리 이어지나 https://cpurams.com/

구글 로보택시 웨이모 사람이 운전하는 것보다 안전 발표 경쟁사 사고 의식? https://newbm.info/

한편, 오타니는 오는 3월 서울 고척스카이돔에서 다저스 유니폼을 입고 첫 경기에 나선다. 샌디에이고 파드리스와의 https://bmopart.com/ 오피사이트

서울 시리즈'가

美캘리포니아에 1시간 만에 한 달 치 폭우 교통사고 사망 https://newbm.info/

범죄 혐의 대통령 후보보다 지지율 훨씬 낮아 벼랑끝 바이든 왜? https://newbm.info/

헝가리 반발 EU 우크라 지원안 28조 규모로 축소해 플랜B 추진-FT https://newbm.info/

포장 열자 마자 으악 日 유명 백화점 케이크에 발칵 https://newbm.info/

흑해 곡물운반선 러시아 기뢰 충돌해 폭발 피해 2명 부상 https://newbm.info/

작성했다. 지난 시즌 손흥민은 스포츠탈장, 안와골절 등 수많은 악재 속에서도 리그 10골 6도움을 올렸다. 하지만 https://bmopart.com/ 오피사이트

이날 어시스트

日정부 후지산 폭발시 화산재 바다에 버리기로 가닥 https://newbm.info/

미국 이스라엘 앞으로 급파한 핵항모 수일 내 철수 https://newbm.info/

목숨걸고 험난한 정글 가는 이유 작년 미국행 이민자 역대 최다 중국인도 https://newbm.info/

헤즈볼라 지도자 야즈벡 레바논 국경서 이군 폭격에 사망 https://newbm.info/

스페이스X 휴대폰 연결 위성 첫 발사 우주 기지국 역할 https://newbm.info/

북미 5대호 얼음 면적 50년 만에 최소 엘니뇨 지구온난화 여파 https://newbm.info/

꾸역 꾸역 늘어난 태양광 발전 중동 석유 재벌 위협하나 https://newbm.info/

함께 거론됐으나, 결국 뉴욕 메츠의 선택은 류현진이 아닌 마네아였던 것이다. 마네아는 2013년 메이저리그 https://bmopart.com/ 오피사이트

신인드래프트

중국이 거부한 日가리비 일본 해결책으로 이 나라 선택했다 https://newbm.info/

11조원 손실 日 강진에 IT 반도체 공장 올스톱 https://newbm.info/

NASA 유인 달 착륙 아르테미스 2026년으로 연기 왜? https://newbm.info/

트럼프 민사재판 최후진술서 또 마녀사냥 뉴욕 檢총장 대가 치러야 https://newbm.info/

미국 스포츠 전문 매체 '디애슬레틱'의 데니스 린은 11일(이하 한국시간) 김하성을 트레이드하는 것이 https://bmopart.com/ 오피사이트

최선의 기회

오늘 올해 첫 민주주의 시험대 판가름 전세계 이목 대만에 쏠리는 이유 https://newbm.info/

트럼프 대세론이냐 헤일리 추격이냐 공화 경선 막 올라 https://newbm.info/

애플 中서 판매 둔화하자 아이폰 가격 인하 주가 또 떨어질듯(상보) https://newbm.info/

헝가리 총리 EU 차원 우크라 지원 반대 해 끼치면 안 돼 https://newbm.info/

발탁돼 이번 2023 CAF 아프리카 네이션스컵에 차출됐다. 하지만 1차전을 앞두고 토트넘 훗스퍼와의 맞대결이 https://bmopart.com/ 오피아트

계획되어 있었다

스마트폰도 AI시대 삼성 인공지능 탑재 갤럭시 S24 첫선 https://newbm.info/

WSJ 러시아의 북한산 미사일 사용 北무기 수출에 새로운 기회 https://newbm.info/

오픈AI CEO 샘 올트먼 AI 칩 생산 네트워크 구축 추진 https://newbm.info/

美공화 디샌티스 후보 사퇴 트럼프 지지 대세론 굳히나 https://newbm.info/

애플 MR 헤드셋 비전 프로 판매 호조에 시총 1위 복귀(종합) https://newbm.info/

트럼프 대세론 vs 헤일리 바람 뉴햄프셔주 결과 곧 공개 https://newbm.info/

브뤼헤의 러브콜을 받아 이적했다. 브뤼헤에서 2021-2022시즌부터 이번 시즌까지 두 시즌 반가량 활약한 누사는 https://bmopart.com/ 오피 건마

62경기에

헤일리 경선에 남는 이유는 트럼프의 사법리스크 https://newbm.info/

황금 용이 휘감은 아날로그 시계 갤 S24 울트라 한정판 가격 얼마? https://newbm.info/

바이든 트럼프 재대결 미국인들에겐 역대급 비호감 선거 https://newbm.info/

중국 춘절 앞두고 대이동 시작 올해 특징은 알뜰하게 https://newbm.info/

잰슨은 보스턴에서 뛰고 있는데 보스턴은 최근 그의 트레이드를 추진하고 있는 것으로 https://bmopart.com/ 오피

알려졌다.

다시 뛰는 비트코인 美 FOMC 앞두고 4만3천달러선 회복 https://newbm.info/

머스크 사람 뇌에 처음으로 텔레파시 칩 이식 https://newbm.info/

美 연준 금리 4연속 동결 행진 뉴욕 증시 약세 마감 https://newbm.info/

뉴욕증시 FOMC 결과 빅테크 실적 주시 속 반등 https://newbm.info/

日 김건희 명품백 보도에 친일 윤석열 물러나면 손해 https://newbm.info/

베이조스 플로리다주로 이사 아마존 주식 5000만주 매각 때문? https://newbm.info/

美 MZ세대 신카 긁고 못 갚아 연체율 12년 만에 최고 https://newbm.info/

친트럼프 하원의장 타격 장관탄핵 이스라엘 단독원조 불발 https://newbm.info/

22개월 만에 다시 여기까지 비트코인 상승세 https://newbm.info/

EU 우크라 침공 러시아 지원한 中 본토기업 제재 추진 https://newbm.info/

ETF에 자금 유입 비트코인 5만2000달러 돌파 https://newbm.info/

우리 할아버지가 개인사까지 꺼낸 장관 미국 마음 돌릴 수 있을까 https://newbm.info/

도쿄도청사 매일 저녁 127m짜리 디스플레이쇼 세계 최대 규모 https://newbm.info/

일본어 모르면 숙박 못해 韓관광객 거부한 日호텔 https://newbm.info/

엔비디아 충격 포드 가격 인하 테슬라 급락 https://newbm.info/

美 지원 불투명해지자 IMF 우크라에 9억달러 지원 임박 https://newbm.info/

美 SK실트론 미국 공장 생산 증대에 7200억원 대출 지원 https://newbm.info/

핵무기 사용 가능성에 이어 AI 무기화 꺼내든 푸틴 https://newbm.info/

중국 유인 달탐사선 이름은 꿈의 배 2030년까지 달에 사람 보낸다 https://newbm.info/

꿈의 땅으로 가보자 미국 국경 넘으려는 중국 중산층 https://newbm.info/

美육군 5년내 정원 2만4천명 감축 특수부대 줄이고 방공 강화 https://newbm.info/

달 탐사선 오디세우스 다리 부러져가동 멈추고 2주 뒤 깨울것 https://newbm.info/

Https://emirates-home.com/carpenter-in-dubai

나스닥 하루만에 사상 최고치 경신 AI 열풍이 상승 흐름 견인 https://newbm.info/

서울 7배 규모 텍사스 최대 산불 원인은 송전선 때문 https://newbm.info/

7만달러 뚫은 비트코인 다음 저항선은 7만6000달러 https://newbm.info/

Https://dubai-cleanup.com/dubai-sofa-cleaning-company

Https://dubai-cleanup.com/anti-ruma-company-in-dubai/

Https://dubai-cleanup.com/insect-control-company-in-dubai

Https://dubai-cleanup.com/kitchen-cleaning-company-in-dubai

Https://dubai-cleanup.com/villa-cleaning-company-in-dubai

日증시 강세에 일본은행 보유 ETF 평가이익만 305조원 https://newbm.info/

고물가 지속에 아르헨장관 1 1행사 말고 실가격으로 판매하라 https://newbm.info/

테슬라 등 주요 車업체 주행 자동화 시스템 안전 불량 https://newbm.info/

총선 승리한 네덜란드의 트럼프 총리도전 일단 좌절 https://newbm.info/

경합주 밀리는 바이든 대선 승부처 블루 장벽 재건에 승부수 https://newbm.info/

몸값 65조 틱톡에 월가 군침 트럼프 최측근도 나섰다 https://newbm.info/

네타냐후 美 압박에 작심발언 건망증 있나 굴복 안 해 https://newbm.info/

득세하는 스트롱맨 트럼프 재선 노리고 푸틴 시진핑 장기집권 https://newbm.info/

인간 뇌에 가까워진다 블랙웰 GPT-4 성능 20배 AI 지원 칩 https://newbm.info/

프랑스 우크라에 군인 2000명 파병 러시아 유럽까지 공격 예고 https://newbm.info/

美 삼성 SK 장비 판매 중단 고무적 中반도체에 서비스 부품 통제 https://newbm.info/

모스크바서 무차별 총격으로 40명 사망 이슬람 무장단체 IS 우리 소행 https://newbm.info/

이 남성이 부르자 판빙빙도 달려갔다 39조원 갑부男의 정체 https://newbm.info/

권도형 없이 미국서 사기혐의 첫 재판 미 규제당국 테라는 사상누각 https://newbm.info/

테슬라 제친 中 BYD 영업이익 급증 https://newbm.info/

먹는거 아냐 日서 난리난 26만원 초코송이 이어폰 https://newbm.info/

ASML 해외 이전 막아라 네덜란드 베토벤 작전 개시 https://newbm.info/

사라진 오타니 통역사 LA 돌아가는 비행기 안 탔다 https://newbm.info/

美대선 리스크 걱정하는 세계 기업들 회사채 발행 서둘러 https://newbm.info/

챗GPT 로그인 없이도 사용 AI 혜택 더 넓게 나눈다 https://newbm.info/

아마존 베이조스 플로리다에 1천200억원짜리 3번째 저택 구입 https://newbm.info/

아마존 웹서비스 수백명 감원 줄잇는 빅테크 군살빼기 https://newbm.info/

Your blog is amazing dude. i love to visit it everyday. very nice layout and content ,

Your blog is amazing dude. i love to visit it everyday. very nice layout and content ,

엔비디아 A M D 주가 급락 대만 지진 여파? https://newbm.info/

테슬라 무인택시 8월 공개? 일론 머스크 트윗에 시간외거래 상승 https://newbm.info/

7년만에 뜨는 검은 태양 수백만명 대이동 진풍경 https://newbm.info/

핵 테러 언급한 러 우크라 이틀 연속 자포리자 원전 때렸다 https://newbm.info/

홍콩 비트코인 ETF 허용할 듯 중국인 투자길 열리나 https://newbm.info/

미 남부 강타한 역대급 폭풍우 오하이오주 향해 돌진 https://newbm.info/

AI가 당신 목숨을 노린다 이스라엘이 불 지핀 AI전쟁 논란 https://newbm.info/

이란 EU 사우디 카타르 통화 이스라엘공격後 지지확보 행보 https://newbm.info/

비트코인 반감기로 채굴업체 울상 약 14조 원 타격 https://newbm.info/

사막 도시 두바이 75년 만의 폭우 하루에 1년치 비 쏟아져 https://newbm.info/

중국 가도 푸바오 못 본다? 잘 먹고 에너지 넘치는데 무슨 일 https://newbm.info/

아이폰 겨누는 화웨이 이번엔 200만원 넘는 퓨라70 출시 https://newbm.info/

넷플릭스 호실적에도 성장 둔화 한계 우려에 하락 https://newbm.info/

테슬라 실적발표 앞두고 차값 줄인하에 머스크 인도 방문도 연기 https://newbm.info/

고금리에도 웃는 美럭셔리 부동산 사상 최고가 기록 https://newbm.info/

美 4월 PMI 4개월 만에 최저 혼란스러운 금리 전망 https://newbm.info/

체감온도 48도 극심한 폭염 닥쳤다 학교 7천곳 대면수업도 중단 https://newbm.info/

미국 한국 일본 네덜란드에 中 반도체 공장 취업 금지하라 https://newbm.info/

국제신문이 만든 다큐멘터리 국내 언론사 첫 칸영화제 공식초청 https://bamminblog.com/

Az adequit cégeladás megbízás típusok magukban foglalják, hogy az eladó cégek tulajdonosait tranzakciós tanácsadással segítik.

Great article. Thank you for sharing your insight on this topic.

I enjoyed reading this post it is very helpful and has informative content thanks for sharing it.

FT 강달러 세 계 경제 위험 초래 https://newbmpage.com/ 디스인플레이션 방해

부산영상위 제작지원 영화 드라마 다큐 14편 선정 https://bamminblog.com/

한국 은행은 투자 잘 못 한다 11년째 금 전혀 안 사는 이유는? https://newbmpage.com/

Leave a Comment